Mongolian University of Science and Technology conducts research on wastewater treatment materials

Society

Ulaanbaatar/MONTSAME/. In recent years, environmental and

ecological issues have become a focus of global attention because climate change, the economy, rapid population

growth, over-centralization, and overgrowth in consumption and services contribute to resource shortages and water, air, and

soil pollution.

Therefore, in 2014, the Government of Mongolia adopted and implemented the ‘Green

Development Policy.’ In other

words, we are introducing environmentally friendly techniques, technologies,

and green products to our country, and we are supporting the production of

environmentally friendly products using our country's mineral resources.

In recent years, researchers from the Center for Materials Science of the

Mongolian University of Science and Technology (MUST) have been conducting

research to produce eco-friendly products using domestic raw materials, saving natural raw materials by using secondary

raw materials, and obtaining green products.

In support of our works, the Korea Institute of Materials Science has been

financing the project ‘Research of wastewater treatment materials’ since 2017 in cooperation with the Center of Materials Science of MUST. The project was

successfully implemented in 2017-2019 and was extended again in 2020.

The Korean Institute of Materials Science was established in 1976 and specialized in metal and ceramic material processing technology, new material development, technology transfer to industry, material properties research and certification, and the supply of innovative products to the industry. The Institute had the status of a sub-institute of the Korean Institute of Mechanical Engineering and Materials Science. It was approved as an independent organization by the National Assembly of the Republic of Korea in April 2020.

Korean Institute of Materials Science

The Institute's researchers developed wind farms, flexible cell

phone screens, solar panels, auto parts, refractories,

and materials for nuclear technology for large companies such as Samsung, LG,

and Hyundai.

The Korean Institute of

Materials Science cooperates with material research institutes in many

countries, such as the Fraunhofer Institute in Germany, the National Institute

of Materials Science in Japan, the Institute of Metallurgy in China, General

Motors Holdings LLC in the United States, Thailand, Indonesia, Ukraine,

Slovenia, Sri Lanka, Vietnam, the Philippines, and Malaysia.

When implementing international projects and programs,

they aim to transfer advanced

technology, develop new materials, exchange experiences with scientists from

partner countries, and build the capacity of researchers.

The Institute

is implementing the KIMS-ASIA project for the second time. Since 2017, the Institute of Materials

Science has worked with material scientists from Mongolia, Cambodia,

Indonesia, and Vietnam on research to develop natural fiber-reinforced

composites, wastewater treatment materials, biodegradable paper for flower

pots, nanocomposite fibers for wearable textile applications and

permanent products to develop magnetic materials.

In addition to conducting research, the Institute organizes international symposium to train young scientists and exchange experiences. An example of it is the successfully-organized Second KIMS-ASIA International Symposium in Ulaanbaatar in June 2018 in collaboration with the School of Applied Sciences (SAS) of the Mongolian University of Science and Technology and the Center for Materials Science.

Second KIMS-ASIA International Symposium

(Opening of the conference by Dr. D. Gankhuyag, Director of the SAS, MUST, June 2018)

In 2019, the third international ‘KIMS-ASIA’ symposium

was organized in Indonesia,

in which scientists of

the Center of Material science of MUST participated.

Opening of the 3rd KIMS-ASIA International Symposium by KIMS President

Jung-Hwan Lee (2019 Institute of Physics, Indonesian Academy of Sciences)

In Mongolia, the proper

use of water resources has become a priority. Therefore, our scientists requested the Korean Institute of Materials Science

to produce water purification materials, first and foremost production

of ceramic membranes using domestic

raw materials at a low cost.

As a result, we are conducting a research to produce ceramic membranes using clay from our country. Membrane technology

is widely used in developed countries, but refined pure oxides use expensive

raw materials such as alumina and zirconium oxide, making it a costly and raw

material-dependent technology.

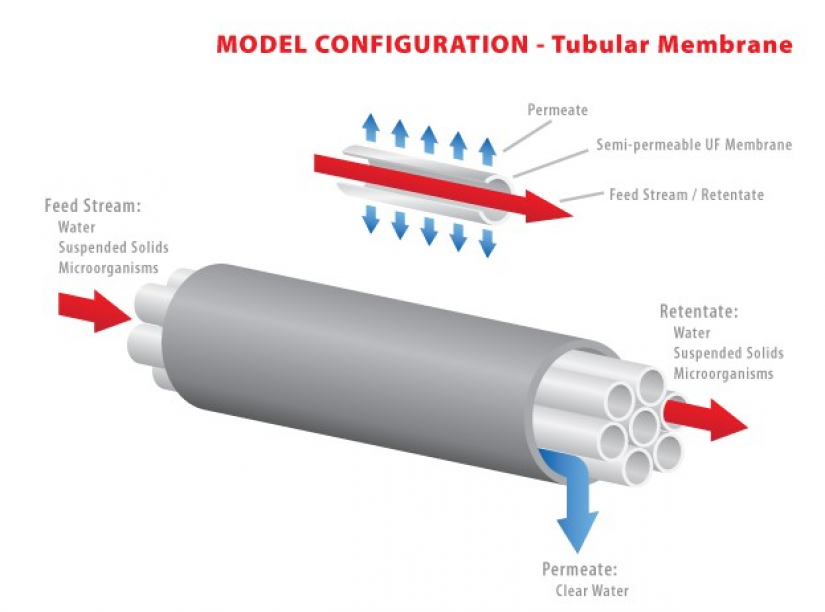

The technology uses a membrane wall

to separate certain parts from the solution. For this purpose,

synthetic and ceramic materials with clear pores are used.

The principle of operation of ceramic membranes

Membranes made of synthetic materials are inexpensive, but have a short

service life and durability. At the same time, since it is not possible to

produce raw materials for synthetic materials in our country, our scientists

have tried to create ceramic membranes using natural raw materials such as

kaolin and other minerals.

Membranes are divided into micro-, ultra-, nano- and reverse osmosis

according to their pore size and can be used for the complete purification of

gray water and to meet drinking water standards.

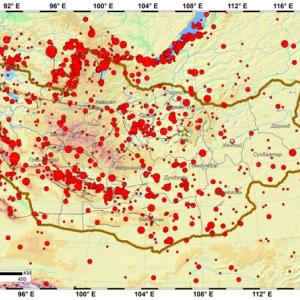

Therefore, in October 2017, Dr. In-Hyuk Song, Head of the Department of Powder Materials and Technical Ceramics at the KIMS, conducted field research with professors and scientists from the Center of Material science of the MUST. They collected many samples of raw materials from Dornogobi, Dundgobi und Tuvaimak’s and analyzed them.

In 2017-2019, scientists from the MUST visited the Korea Institute of Materials Science to conduct research on the Mongolian raw materials.

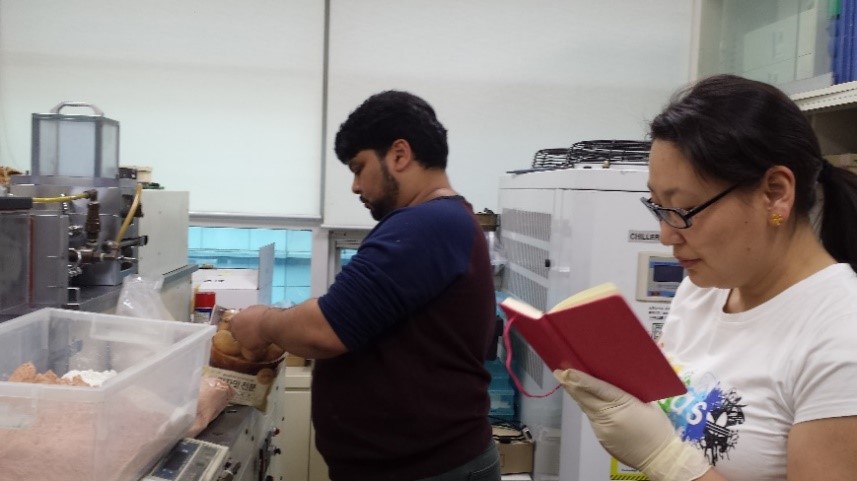

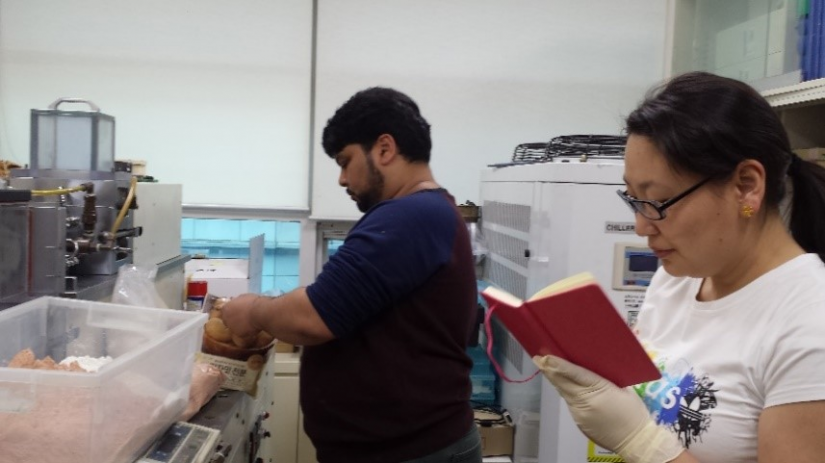

Dr. Abbas, KIMS, R.Dolgorjav and S.Bayarjargal, lecturer of UST, conducts experiments on ceramic membrane support, April and August 2019

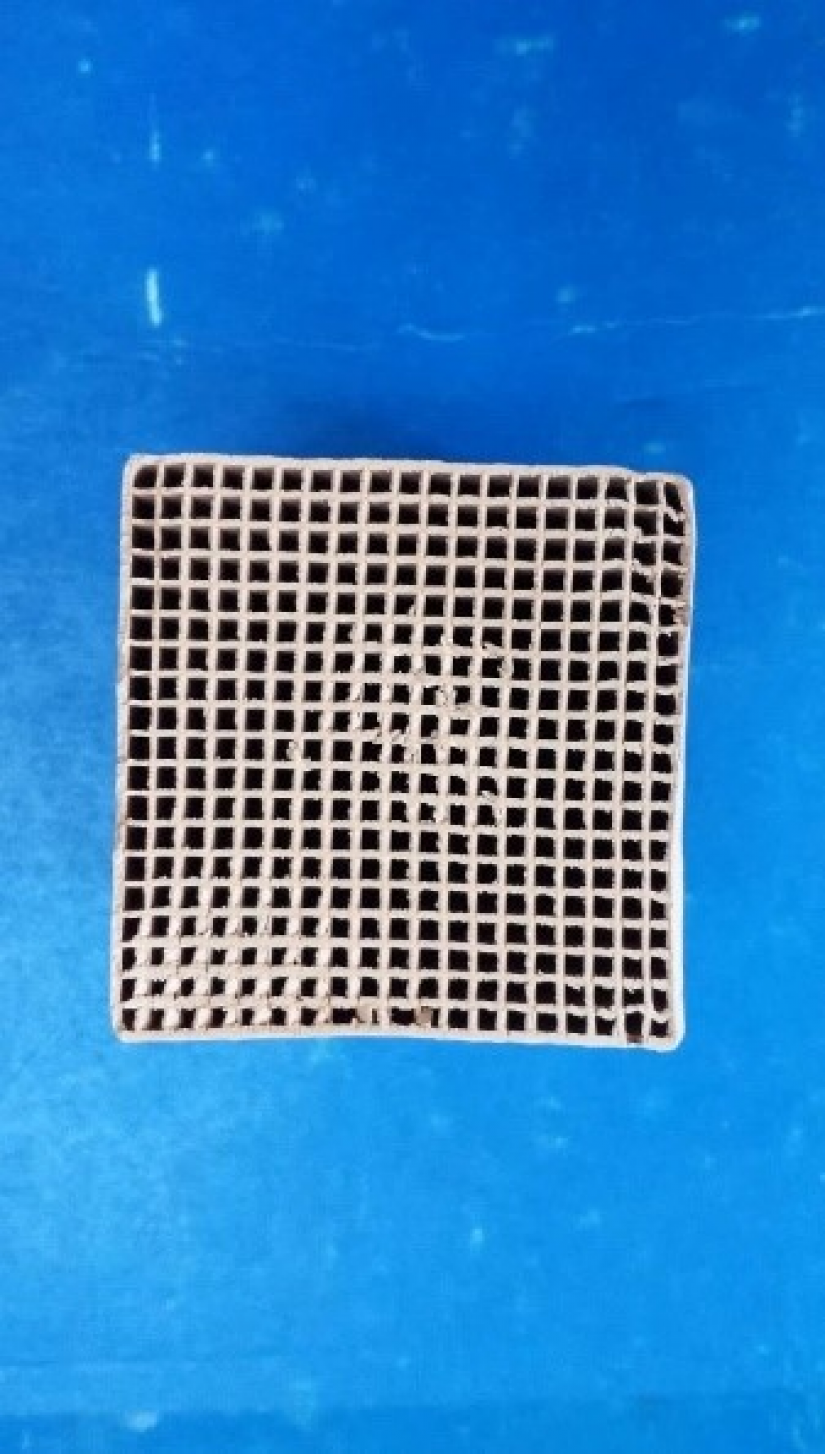

Ceramic membrane supports of various shapes, made

using domestic raw materials

In the years

2017-2018, tests were conducted to determine the properties of Mongolian raw

materials, such as the chemical composition, mineral composition, and particle

composition, followed by ceramic technological experiments.

As a result of

the ceramic technological experiments, important parameters such as the raw

material composition and burning temperature for the production of ceramic

membranes were determined.

In the years

2018-2019, our scientists successfully extracted ceramic membrane

carriers and conducted water permeability and wastewater filtration

experiments.

As a result, a 174-250 nm porous body was obtained using domestic clay, and it was determined that an ultra-filter ceramic membrane could be obtained after coating.

Source: Mongolian University of Science and Technology

Ulaanbaatar

Ulaanbaatar